-

We will establish the commercial viability of Wire Additive Manufacturing while collecting baseline data to prepare for a Phase II SBIR through a three stage research process:

- 1: Acqusition and Curriculum Writing

- 2: Integrator Training

- 3: Intern Program

-

The Team:

- Grisha: FTE Principal Investigator and Project Manager

- Connecticut Center for Advanced Technology: Develop Base Core Curriculum. Deliver WAM Integrator training

- Todd Schwendemann, SCSU Center of Nanotechnology: Program and curriculum evaluator

-

As an SBIR Team we will focus on the following goals:

- Duplicable Process and Procedures

- Integrator Recruitment and Retention

- Intern Career Pathway Development

-

callback to

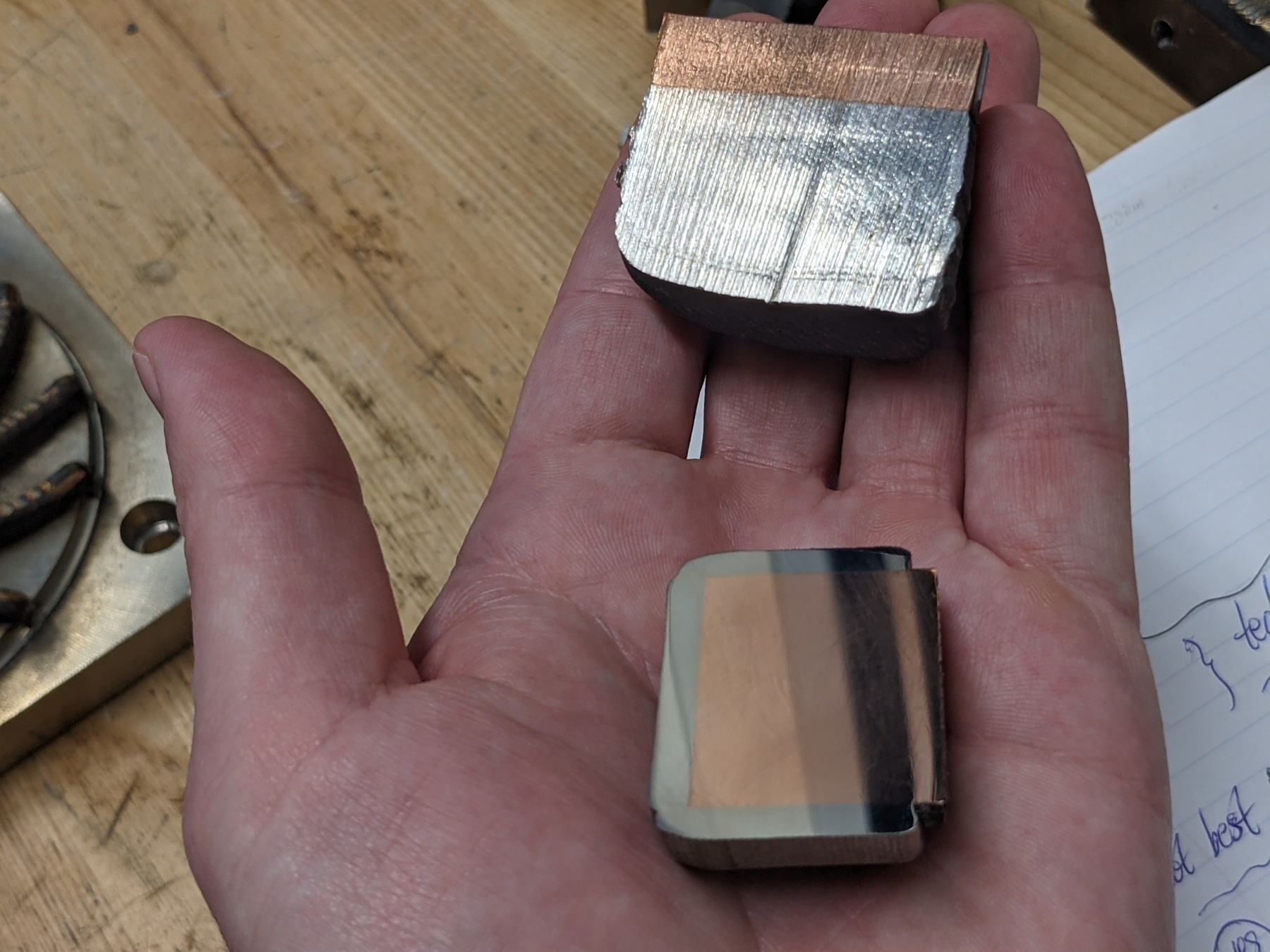

Wire Additive Manufacturing leads to savings. You know what breaks a bunch? Stuff you pour liquid metal into.

Casting replacement, parts replacement, reducing parts of origin, imagine subs doing WAM repairs while out at sea

-

Rewind to

Instead of subtracting, additive manufacturing works like a 3D printer. Hybrid models add and subtract materials. This also improves security.

Rick and Grisha expect to have many contracts with the 7021 clause, which means CMMC. Wire Additive = less data flow

-

Back to

C&C Metals Inc. makes big parts for submarines. Imagine hot metal poruing into a casting. Takes two years to get castings approved for shipbuilding and one year for repair castings.

Then 500 lbs of raw material, $15,000 later, gets shaped into 44 lbs part.

Slow. Too slow

-

In reply to

The Team will focus on the immediate commercial applicability of Wire Additive manufacturing while demonstrating the increased, speed, security, and savings to deliver ship building readiness.

Navy cannot deliver increased Columbias doing the same thing over

-

Jeff will join the SBIR bid team I have built for C&C Metals inc. The core values of CCAT align well. In fact Rick Corbiski had a tinge of jealousy looking at the support CT manufactuers in state.

Think Like Customers

Constantly Innovate

Be Acccountable

We are All In

-

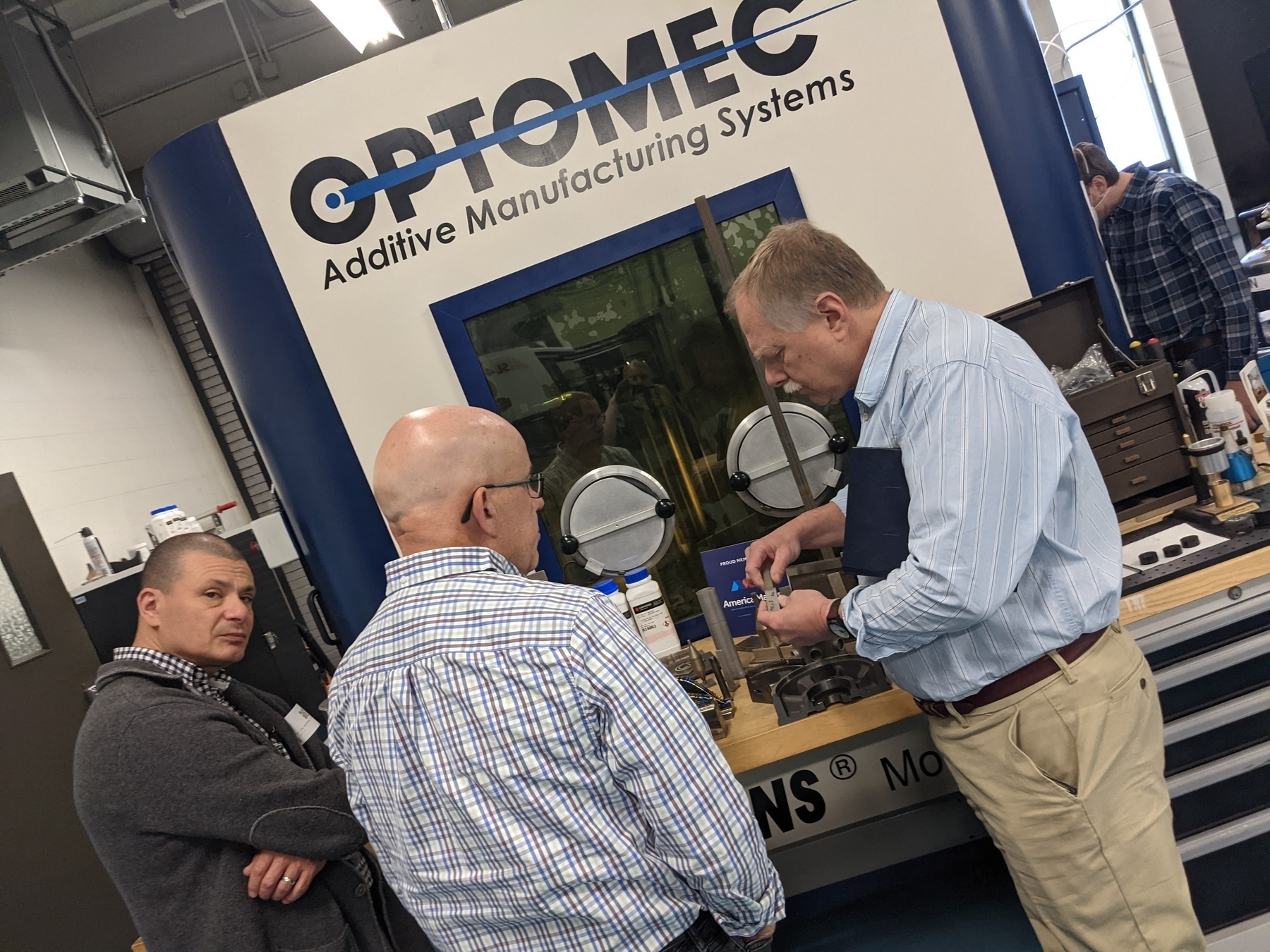

Spent Friday at Connectict Center for Advanced Technology meeting with Jeff Crandall and Rick and Grisha of C & C Metals, Inc.

We took a tour of the Center and then got cracking on an SBIR NSF award we will submit for additive manufacturing

subscribe via RSS